Drop Test Machine | Drop Tester Manufacturer | Linkotest from Sunny Islam's blog

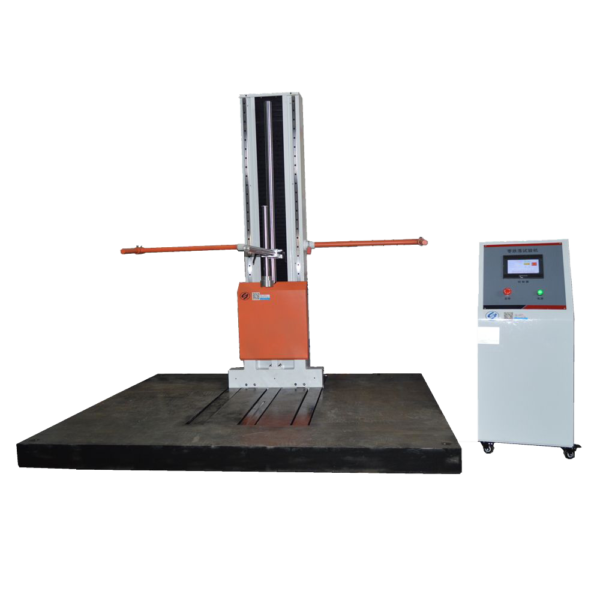

A drop test machine

serves a crucial role in assessing the durability of product packaging and

determining the impact resistance of items during transportation and handling.

This specialized equipment, known as a drop tester, is instrumental in subjecting

specimens to controlled drop tests to simulate real-world scenarios and

evaluate their structural integrity.

The primary

objective of using drop testers is to mimic the effects of accidental drops on

products, thereby gauging their ability to withstand impact forces. By

maintaining the orientation of the specimen during the drop and closely

analyzing the subsequent damage, manufacturers can gain valuable insights into

the performance and durability of their products.

Moreover, drop

testers find applications across a wide range of industries beyond electronics

and electrical equipment. They play a vital role in conducting drop tests for

diverse sectors such as medicine, food, and pharmaceuticals, where the safe

transportation of fragile or sensitive items is paramount.

For more than 23

years, Linkotest has been a trusted provider of high-quality mechanical drop

testers tailored to the needs of the drop test industry. Their extensive range

of offers includes mobile product drop testers, rotating drum testers, package

drop testers, and specialized testers for large items. This longstanding

commitment to delivering reliable testing solutions underscores Linkotest's

reputation as a leading player in the field.

In

conclusion, drop test machines are indispensable tools for manufacturers

seeking to ensure the robustness and resilience of their products under

real-world conditions. Linkotest's comprehensive range of drop testers caters

to a diverse set of industries and stands as a testament to their expertise and

dedication in serving the drop test industry for over two decades.

The Wall